|

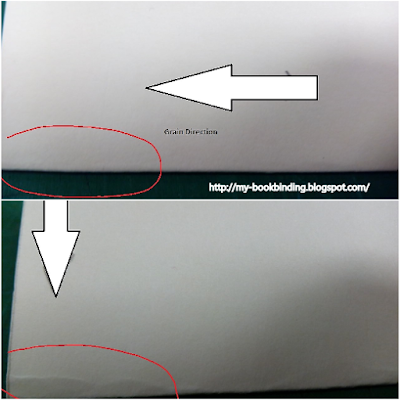

| Folding paper to the grain direction |

As a conservator and bookbinders deal with several materials especially paper-based material, it is important to understand the paper grain direction theory and get a practical training about determining the grain direction for several paper-based materials whether it is machine made or handmade.In this blog, I will use samples from several and different paper materials and demonstrate the importance of understanding paper grain direction.

What is paper grains?

A paper's grain is the direction which most of the fibers align in a specific orientation. Grain is determined during the paper making process when fibers tend to align in one direction or the other.Is it important to know the grain direction?

Paper is susceptible to any moisture, so it is important to know the paper grain direction.

For binding

It is ideal to have the grain of the pages, endpapers, lining paper, and boards used for the case...etc. to be barreled with the book spine, in order to eliminate the unnecessary stress on the hinges and for the ease of turning the pages.

For paper restoration (paper mending)

Normally we are using Japanese paper for conservation and restoration process especially in paper mending, suppliers now a days providing a mechanical made Japanese paper and tissue (unless they say it is handed mad), so knowing the grain direction for mending paper well be as the same concept of having the grain direction barreled to the gutter or to the spine or to be as the same direction as the original paper. So that, old paper (original) and new paper (that we use for mending) have their tension factor and did not act differently with the temperature and humidity changes.

For customized box and mount making

when the grain direction for all customized box materials and customized document mounts is parallel to its hinges, it will open flat with the grain and last longer.

It is ideal to have the grain of the pages, endpapers, lining paper, and boards used for the case...etc. to be barreled with the book spine, in order to eliminate the unnecessary stress on the hinges and for the ease of turning the pages.

For paper restoration (paper mending)

Normally we are using Japanese paper for conservation and restoration process especially in paper mending, suppliers now a days providing a mechanical made Japanese paper and tissue (unless they say it is handed mad), so knowing the grain direction for mending paper well be as the same concept of having the grain direction barreled to the gutter or to the spine or to be as the same direction as the original paper. So that, old paper (original) and new paper (that we use for mending) have their tension factor and did not act differently with the temperature and humidity changes.

For customized box and mount making

when the grain direction for all customized box materials and customized document mounts is parallel to its hinges, it will open flat with the grain and last longer.

Short grain and Long grain.

It is depending on how it was cut in relation to its grain direction. For example, when the grain direction moves parallel to a paper short side that means it is short grain,

On the other hand, if the grain direction is parallel to the long side (like most of A4 Paper that we use in printers) it called a long grain. So if the grain direction is as long as the length of the whole piece of paper, then it is a long grain sheet.

For example:

- if we have an 11×17 sheet of paper, the grain is running parallel to the 17-inch edge of the sheet and is referred to as Long Grain.

- If the paper is 17×11, then the grain is running parallel to the 11-inch edge of the paper and is referred to as Short Grain.

Mechanical made papers & Handmade papers grain direction!

Once you get a mechanically made paper that means for sure you have a grain direction and this is because of the mechanism of paper making machines,

during the paper manufacturing process a bulb path with what called mesh screening is to be used instead of using a mold frame in handmade paper making, the machine using mesh screening which is moving on relays with running water and mold continually, making paper rolls, the direction which is the bulb is running throw the mesh screening makes the fibers mostly aligned in the same direction of the bulb and mash screening movement. this movement direction is the grain direction for the mechanically made paper after drying.

In opposite side, Handmade papers do not typically have a grain direction because all the fibers that make up the paper lay in all different directions when it is dried.

during the paper manufacturing process a bulb path with what called mesh screening is to be used instead of using a mold frame in handmade paper making, the machine using mesh screening which is moving on relays with running water and mold continually, making paper rolls, the direction which is the bulb is running throw the mesh screening makes the fibers mostly aligned in the same direction of the bulb and mash screening movement. this movement direction is the grain direction for the mechanically made paper after drying.

|

| Bulb movement direction during mechanical paper mad process |

In opposite side, Handmade papers do not typically have a grain direction because all the fibers that make up the paper lay in all different directions when it is dried.

|

| Handmade paper |

What if folding in a wrong grain direction (against the grain direction)?

Generally, In folding against the grain, you are folding the fibers. This cause weakens or split for the fibers, resulting in cracks and tears in the paper-based materials.

|

| Folding effect with and against grain direction |

|

| Folding against grain direction - card |

|

| Folding with the grain direction - card |

Easy ways to determine the paper grain direction, please see this video.

5 Methods to determine the paper grain direction and know the effects of folding papers in the wrong direction.

-----------------------

Creating a Knowledge Sharing Culture

Sherif Afifi

--------------------------------------------------------------------------------------------------------------------

Sorry English is not my first language but sharing experience is a global language

Excellent blog! Great explaining :)

ReplyDeleteThank you

Delete